We analyze your business model, processes, costs and sales mix.

We offer insights, developments and investment programs.

We improve your business in a constantly evolving digital world.

What we do

Designed for you, developed for your business.

OVER 20 YEARS OF IN-HOUSE EXPERIENCE IN BUILDING AN INTEGRATED PLATFORM OF SOLUTIONS AND PROGRAMS FOR THE INDUSTRY all coming together under a new banner QONCEPT.

It all started with basic feasibility studies and soon developed into groundbreaking end-to-end efficiency and plant optimisation tools known as the Concept Engineering program.

More recently the Business Analytics unit developed bespoke tools to integrate broader business metrics into engineering investment and optimisation, and the latest development has been the introduction of Artificial Intelligence benefits into the process providing unique insights and self-learning capabilities into the business and engineering mix.

- Feasibility studies

- End-to-end efficiency

- Planning and plant optimisation

- Return on investment Analysis and Modelling

- Artificial Intelligence capability

The tools within QONCEPT have been developed by a team of highly skilled and knowledgeable Engineers, Operations Specialists, Financial Partners all with a granular knowledge and experience of your industry.

OUR OFFER

Tools & Programs

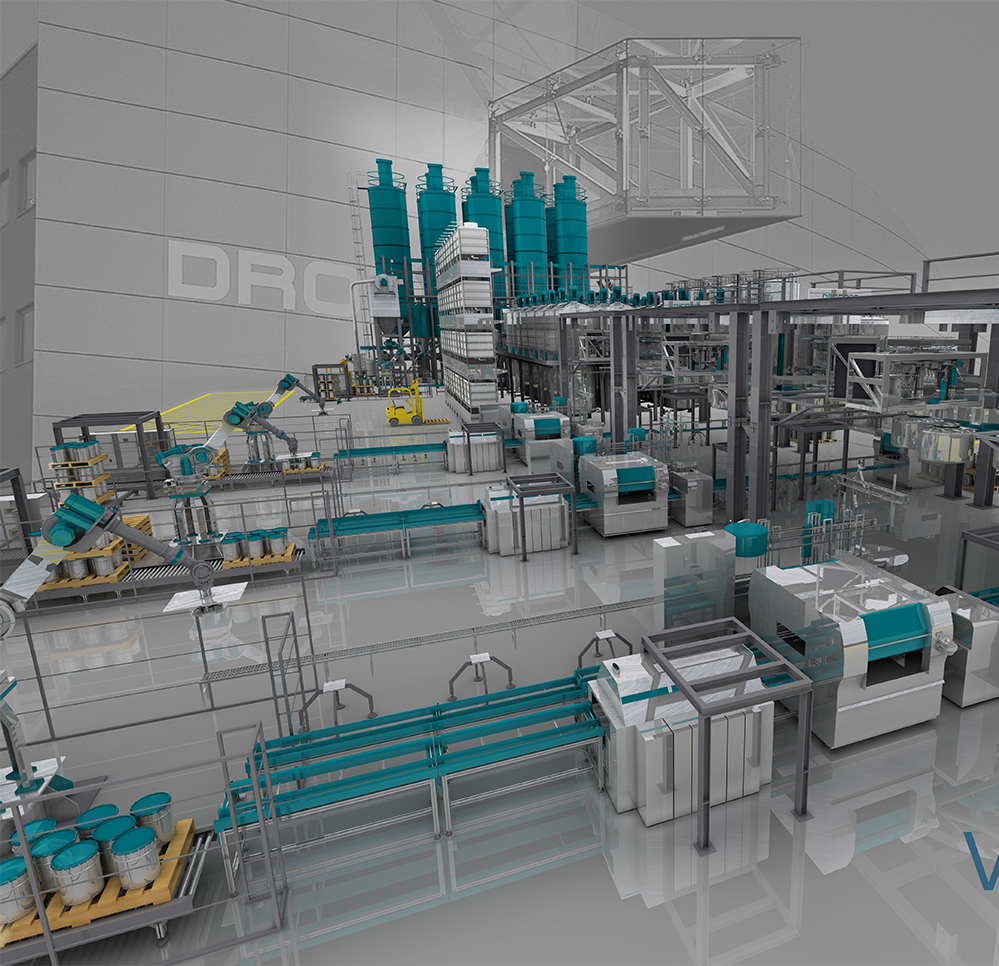

We provide a full set of strategic consulting, business analytics and modelling solutions developed to lower production costs and increase efficiency and productivity, further enhanced by the implementation of the unrivalled DROMONT and COMEC technologies and machinery.

Qoncept Concept Engineering – QCE

The DromontGroup’s original and well established analytics program.

Developed and designed specifically to support our partners capital investment programs, QCE has been utilised for our partners benefit on virtually every single major project over the last 10 years.

QCE can be utilised in small operations but its greatest value is when its employed in full scale turnkey projects. Here with the collection of project base data added to process data modelling we can provide full modelling, data and documentation to support the change process.

From start to finish to the full commissioning of your facility, Qoncept will ensure we will be with you all the way.

Qoncept Business Analytics – QBA

Economic modelling for product, scheduling and engineering investment programs.

Qoncept Business Analytics, QBA, is one of the newest and most exciting skill sets developed by the DromontGroup. Born out of the desire to create economic modelling and returns to support Concept Engineering propositions, QBA has now extended its reach and scope to supporting complete business change, product portfolio alignment, raw material optimisation and Lean processes.

QBA is our own in-house 360 strategic consulting service. Able to analyze multiple inputs incorporating historical, raw material, product, production, scheduling, inventory movements and sales data. QBA can provide you with detailed proposals for change and its impacts across your business. Use QBA to support capital Investment programs, use QBA to help support raw material and product portfolio investment programs.

Qoncept Artificial Intelligence Analytics – QAI

Predictive maintenance and cycle time optimisation through a series of self-learning algorithm tools.

The newest and one of the most exciting development areas of or Group. The ability to incorporate self-learning tools and programs into our machines, processes and monitoring procedures creates significant future benefits. Potentially lowering routine maintenance, anticipating stress points and predicting future patterns all create exciting possibilities for enhanced productivity and profitability.

Dromont

Dromont has now been producing inplant dispensing systems for factory applications and Retail tinting machines with 1000 factory inplant and lab installations and many thousands of Retail machines world-wide, as well as providing advanced technologies in the e-commerce market.

OUR OFFER

Tools & Programs

We provide a full set of strategic consulting, business analytics and modelling solutions developed to lower production costs and increase efficiency and productivity, further enhanced by the implementation of the unrivalled DROMONT and COMEC technologies and machinery.

Qoncept Concept Engineering – QCE

The DromontGroup’s original and well established analytics program.

Developed and designed specifically to support our partners capital investment programs, QCE has been utilised for our partners benefit on virtually every single major project over the last 10 years.

QCE can be utilised in small operations but its greatest value is when its employed in full scale turnkey projects. Here with the collection of project base data added to process data modelling we can provide full modelling, data and documentation to support the change process.

From start to finish to the full commissioning of your facility, Qoncept will ensure we will be with you all the way.

Qoncept Business Analytics – QBA

Economic modelling for product, scheduling and engineering investment programs.

Qoncept Business Analytics, QBA, is one of the newest and most exciting skill sets developed by the DromontGroup. Born out of the desire to create economic modelling and returns to support Concept Engineering propositions, QBA has now extended its reach and scope to supporting complete business change, product portfolio alignment, raw material optimisation and Lean processes.

QBA is our own in-house 360 strategic consulting service. Able to analyze multiple inputs incorporating historical, raw material, product, production, scheduling, inventory movements and sales data. QBA can provide you with detailed proposals for change and its impacts across your business. Use QBA to support capital Investment programs, use QBA to help support raw material and product portfolio investment programs.

Qoncept Artificial Intelligence Analytics – QAI

Predictive maintenance and cycle time optimisation through a series of self-learning algorithm tools.

The newest and one of the most exciting development areas of or Group. The ability to incorporate self-learning tools and programs into our machines, processes and monitoring procedures creates significant future benefits. Potentially lowering routine maintenance, anticipating stress points and predicting future patterns all create exciting possibilities for enhanced productivity and profitability.

Dromont has now been producing inplant dispensing systems for factory applications and Retail tinting machines with 1000 factory inplant and lab installations and many thousands of Retail machines world-wide, as well as providing advanced technologies in the e-commerce market.

Comec 50 years of drawing inspiration through cutting-edge dispersing, milling and filling and highly customized Coating Process Engineering.

KPIs

Business indicators

The modelling created through the various Qoncept Programs provides game-changing Key Performance

indicators for our partners, bringing their business to next level.

Raw Material Utilisation/Reduction

Optimisation of Capacity

Control of Labour Hours

Batch Optimisation

Investement Payback

Inventory Reduction

Profitability

100%

85%

75%

65%

55%

45%

35%

KPIs

Business indicators

The modelling created through the various Qoncept Programs provides game-changing Key Performance

indicators for our partners, bringing their business to next level.

Raw Material Utilisation/Reduction

80%

Optimisation of Capacity

65%

Control of Labour Hours

55%

Batch Optimisation

45%

Investement Payback

35%

Inventory Reduction

25%

Profitability

20%

THEY SAY ABOUT US

Client Stories

Eastern Europe

We were satisfied with the outcome where we have created scope to fulfil the strategic expansion within the level of capital investment originally expected. We have also been able to develop our internal processes to match and accommodate these new capabilities. The Qoncept Program and the skill and knowledge of the team at the DromontGroup were critical to this success.

PROJECT KVIL, Russia

Kvil is a family owned Paint and Coatings Company based in Russia.

Problem statement

Kvil has a large assortment of formulas offering products across the Coatings categories but also differing quality levels within individual categories.

The business had grown quickly and had an excellent reputation for both quality and service. Maintaining these key customer requirements of quality and service and meeting service level expectations while the product portfolio grew was proving a challenge to the management team and threatened the long term growth potential.

Prior to meeting the DromontGroup the owners of Kvil had envisaged future growth would involve the building of a significantly larger new factory and a large investment in a range of capital equipment. All of this was envisaged to accommodate the volume growth, the diversity in formula growth and the resultant growth in raw materials and finished goods.

What did the Dromont Group do for Kvil?

After an initial meeting between Kvil and the DromontGroup a full review was commissioned employing the full range of Qoncept tools. The reviews scope began with the current and future business strategy of Kvil. The impacts of this strategy and resultant growth on raw materials, formulas, packaging variations, batch sizes, batch frequency, finished goods inventory and fundamental to all of this cost. A number of significant other variables were overlaid on this namely seasonality and the expected irregularity of the growth pattern.

Over a period of 90 days the Qoncept Tools were utilised to organise all of these datapoints and variables and a Value Chain Plan and Process Plan created that matched and supported Kvil’s exciting growth strategies.

In summary Kvil was able to undertake a full scale development of its manufacturing process supported by data driven support. The capital investment proposition was reset and further explored and re-justified through Qoncept.

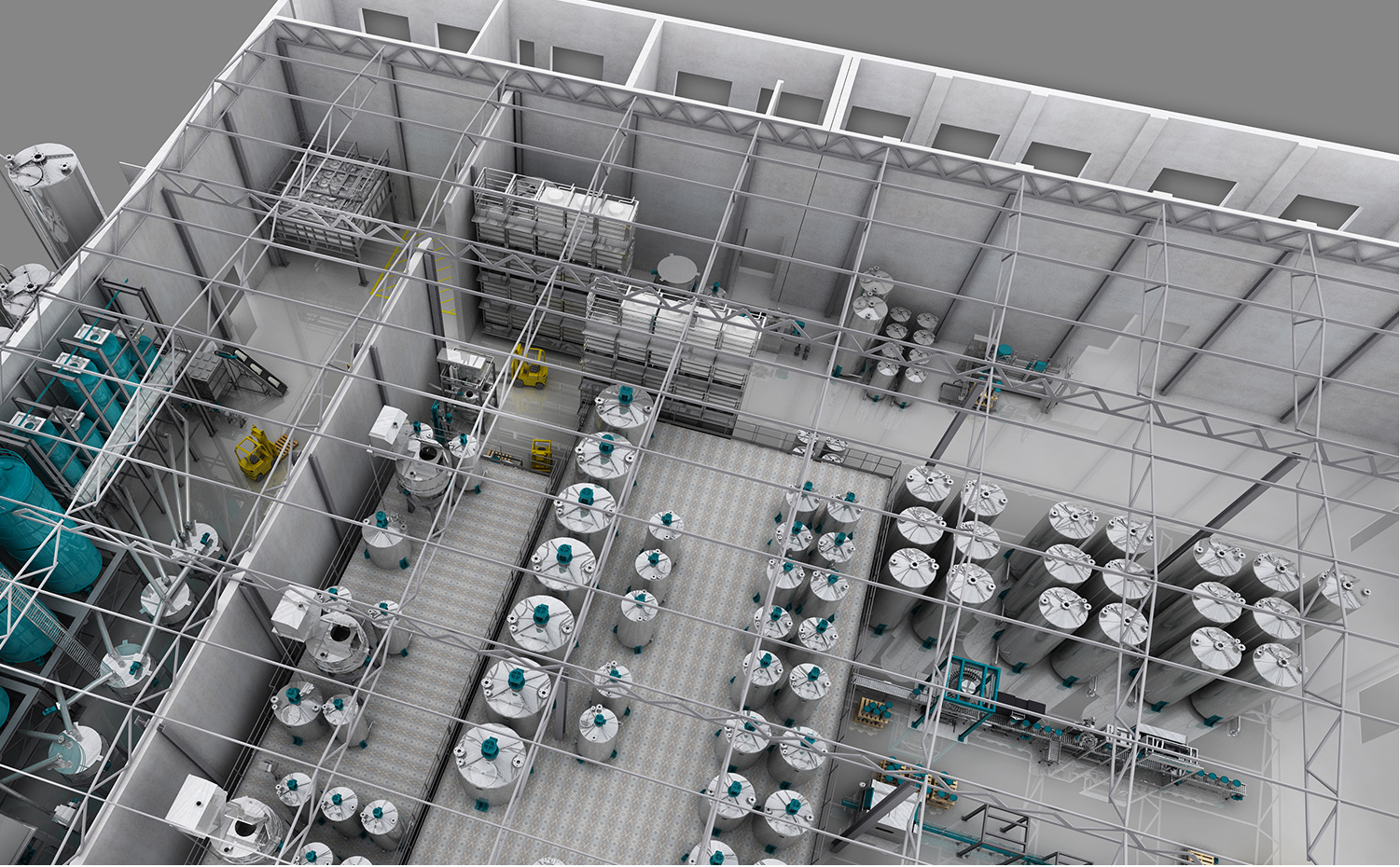

The final output enabled a significant reduction from the originally envisaged plant size, reducing anticipated construction costs and ongoing energy and maintenance costs. The Qoncept programs enabled the smart usage of raw material handling and holding, identified tools to accelerate dispersing and dispensing and utilise the latest thinking regarding Inline filling technology. These smart technologies also enabled a high level of flexibility being built into the plant and plant processes, reducing significantly the original Capital Investment budget.

PROJECT BOYSEN, Philippines

Pacific Paint (Boysen) Philippines, Inc. is the leading paint manufacturer in the Philippines.

Problem statement

We had an urgent need to move our solvent based production facility from its original city centre location to a more appropriate purpose built facility in an industrial area.

In relocating the facility we also had the desire to modernise our production and production processes. We knew that some manufacturers were taking a radical approach to restructuring their processes with some quite startling results. We researched potential partners and through a process of research and recommendation we were introduced to the Dromont Group.

What did the Dromont Group do for BOYSEN?

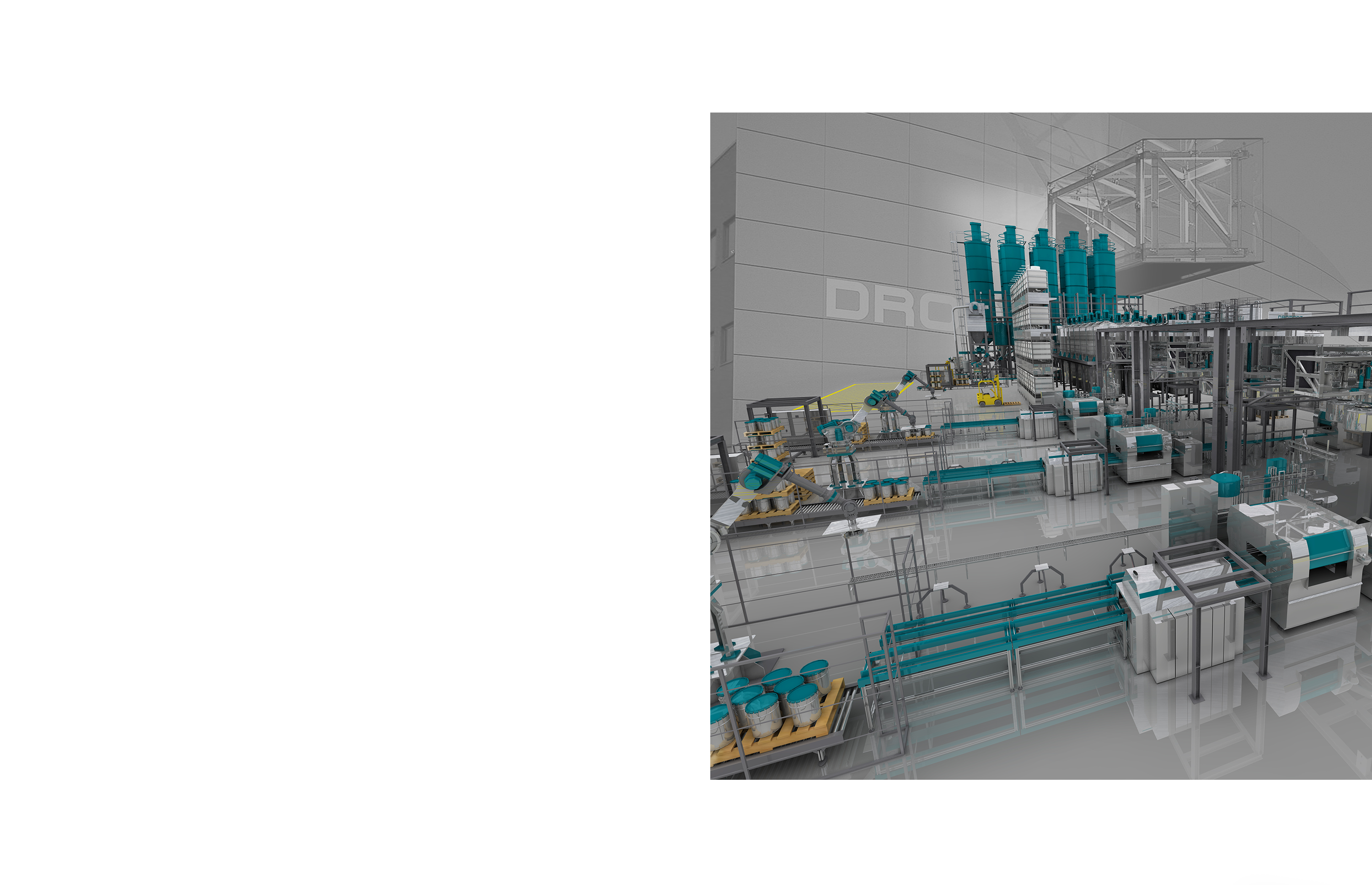

Initially using the full range of Qoncept tools we analysed the complete production data of the old factory, evaluated the raw material and product portfolio and carried out a complete risk assessment. From this analysis we modelled potential changes in raw materials, product portfolio, production and finished goods. Essentially we modelled the entire Value Chain. From that data bank we then with considerable collaboration built a complete model for a new factory with all the associated plant and equipment.

Boysen added certain specifications to our proposal

1. Boysen wanted significant flexibility. Small colored batches, but also the possibility of making large colored batches within the same process. Incorporation of a wide variety of diverse formula families and products: alkyd coating, primers, aluminium paints, road paints.

Solution: Comec dispersion system for the preparation of concentrated dyes (colorant concentrated). Big dispersers to make large batches and we supplied Selecta and Micro xto make small batches.

2. They wanted to build this new factory without disrupting production or stopping the existing factory.

Solution: through the extensive modelling and project planning functionality of Qoncept no business disruption was created through the entire change process.

Asia Pacific

From this analysis we were able to model potential changes in raw materials, product portfolio, production and finished goods. Essentially we modelled the entire Value Chain. From that data bank we built a complete model for a new factory with all the associated plant and equipment.

PROJECT BOYSEN, Philippines

Pacific Paint (Boysen) Philippines, Inc. is the leading paint manufacturer in the Philippines.

Problem statement

We had an urgent need to move our solvent based production facility from its original city centre location to a more appropriate purpose built facility in an industrial area.

In relocating the facility we also had the desire to modernise our production and production processes. We knew that some manufacturers were taking a radical approach to restructuring their processes with some quite startling results. We researched potential partners and through a process of research and recommendation we were introduced to the Dromont Group.

What did the Dromont Group do for BOYSEN?

Initially using the full range of Qoncept tools we analysed the complete production data of the old factory, evaluated the raw material and product portfolio and carried out a complete risk assessment. From this analysis we modelled potential changes in raw materials, product portfolio, production and finished goods. Essentially we modelled the entire Value Chain. From that data bank we then with considerable collaboration built a complete model for a new factory with all the associated plant and equipment.

Boysen added certain specifications to our proposal

1. Boysen wanted significant flexibility. Small colored batches, but also the possibility of making large colored batches within the same process. Incorporation of a wide variety of diverse formula families and products: alkyd coating, primers, aluminium paints, road paints.

Solution: Comec dispersion system for the preparation of concentrated dyes (colorant concentrated). Big dispersers to make large batches and we supplied Selecta and Micro xto make small batches.

2. They wanted to build this new factory without disrupting production or stopping the existing factory.

Solution: through the extensive modelling and project planning functionality of Qoncept no business disruption was created through the entire change process.

PROJECT BOYSEN, Philippines

Pacific Paint (Boysen) Philippines, Inc. is the leading paint manufacturer in the Philippines.

Problem statement

We had an urgent need to move our solvent based production facility from its original city centre location to a more appropriate purpose built facility in an industrial area.

In relocating the facility we also had the desire to modernise our production and production processes. We knew that some manufacturers were taking a radical approach to restructuring their processes with some quite startling results. We researched potential partners and through a process of research and recommendation we were introduced to the Dromont Group.

What did the Dromont Group do for BOYSEN?

Initially using the full range of Qoncept tools we analysed the complete production data of the old factory, evaluated the raw material and product portfolio and carried out a complete risk assessment. From this analysis we modelled potential changes in raw materials, product portfolio, production and finished goods. Essentially we modelled the entire Value Chain. From that data bank we then with considerable collaboration built a complete model for a new factory with all the associated plant and equipment.

Boysen added certain specifications to our proposal

1. Boysen wanted significant flexibility. Small colored batches, but also the possibility of making large colored batches within the same process. Incorporation of a wide variety of diverse formula families and products: alkyd coating, primers, aluminium paints, road paints.

Solution: Comec dispersion system for the preparation of concentrated dyes (colorant concentrated). Big dispersers to make large batches and we supplied Selecta and Micro xto make small batches.

2. They wanted to build this new factory without disrupting production or stopping the existing factory.

Solution: through the extensive modelling and project planning functionality of Qoncept no business disruption was created through the entire change process.

THEY SAY ABOUT US

Client Stories

Eastern Europe

We were satisfied with the outcome where we have created scope to fulfil the strategic expansion within the level of capital investment originally expected. We have also been able to develop our internal processes to match and accommodate these new capabilities. The Qoncept Program and the skill and knowledge of the team at the DromontGroup were critical to this success.

PROJECT KVIL, Russia

Kvil is a family owned Paint and Coatings Company based in Russia.

Problem statement

Kvil has a large assortment of formulas offering products across the Coatings categories but also differing quality levels within individual categories.

The business had grown quickly and had an excellent reputation for both quality and service. Maintaining these key customer requirements of quality and service and meeting service level expectations while the product portfolio grew was proving a challenge to the management team and threatened the long term growth potential.

Prior to meeting the DromontGroup the owners of Kvil had envisaged future growth would involve the building of a significantly larger new factory and a large investment in a range of capital equipment. All of this was envisaged to accommodate the volume growth, the diversity in formula growth and the resultant growth in raw materials and finished goods.

What did the Dromont Group do for Kvil?

After an initial meeting between Kvil and the DromontGroup a full review was commissioned employing the full range of Qoncept tools. The reviews scope began with the current and future business strategy of Kvil. The impacts of this strategy and resultant growth on raw materials, formulas, packaging variations, batch sizes, batch frequency, finished goods inventory and fundamental to all of this cost. A number of significant other variables were overlaid on this namely seasonality and the expected irregularity of the growth pattern.

Over a period of 90 days the Qoncept Tools were utilised to organise all of these datapoints and variables and a Value Chain Plan and Process Plan created that matched and supported Kvil’s exciting growth strategies.

In summary Kvil was able to undertake a full scale development of its manufacturing process supported by data driven support. The capital investment proposition was reset and further explored and re-justified through Qoncept.

The final output enabled a significant reduction from the originally envisaged plant size, reducing anticipated construction costs and ongoing energy and maintenance costs. The Qoncept programs enabled the smart usage of raw material handling and holding, identified tools to accelerate dispersing and dispensing and utilise the latest thinking regarding Inline filling technology. These smart technologies also enabled a high level of flexibility being built into the plant and plant processes, reducing significantly the original Capital Investment budget.

Asia Pacific

From this analysis we were able to model potential changes in raw materials, product portfolio, production and finished goods. Essentially we modelled the entire Value Chain. From that data bank we built a complete model for a new factory with all the associated plant and equipment.

PROJECT BOYSEN, Philippines

Pacific Paint (Boysen) Philippines, Inc. is the leading paint manufacturer in the Philippines.

Problem statement

We had an urgent need to move our solvent based production facility from its original city centre location to a more appropriate purpose built facility in an industrial area.

In relocating the facility we also had the desire to modernise our production and production processes. We knew that some manufacturers were taking a radical approach to restructuring their processes with some quite startling results. We researched potential partners and through a process of research and recommendation we were introduced to the Dromont Group.

What did the Dromont Group do for BOYSEN?

Initially using the full range of Qoncept tools we analysed the complete production data of the old factory, evaluated the raw material and product portfolio and carried out a complete risk assessment. From this analysis we modelled potential changes in raw materials, product portfolio, production and finished goods. Essentially we modelled the entire Value Chain. From that data bank we then with considerable collaboration built a complete model for a new factory with all the associated plant and equipment.

Boysen added certain specifications to our proposal

1. Boysen wanted significant flexibility. Small colored batches, but also the possibility of making large colored batches within the same process. Incorporation of a wide variety of diverse formula families and products: alkyd coating, primers, aluminium paints, road paints.

Solution: Comec dispersion system for the preparation of concentrated dyes (colorant concentrated). Big dispersers to make large batches and we supplied Selecta and Micro xto make small batches.

2. They wanted to build this new factory without disrupting production or stopping the existing factory.

Solution: through the extensive modelling and project planning functionality of Qoncept no business disruption was created through the entire change process.

OUR MARKET

Industries and Sectors

Originally developed for the paint and coating sector, QONCEPT has now been further developed so that it can be applied to all Market and Sectors

COATING & INKS

Leading Engineering Solutions

CHEMICALS

The key to Raw Material Optimisation

FOOD

Driving Value Chain Optimisation

PHARMA

Small Scale, High Speed

COSMETICS

The Beauty of Technology

OUR MARKET

Industries and Sectors

Originally developed for the paint and coating sector, QONCEPT has now been further developed so that it can be applied to all Market and Sectors

COATING & INKS

Leading Engineering Solutions

CHEMICALS

The key to Raw Material Optimisation

FOOD

Driving Value Chain Optimisation

PHARMA

Small Scale, High Speed

COSMETICS

The Beauty of Technology